AquaVoda Develop New Silicon Carbide Membrane Skid

Fully designed and fabricated in Western Australia, this groundbreaking AquaVoda Silicon Carbide Membrane Skid has

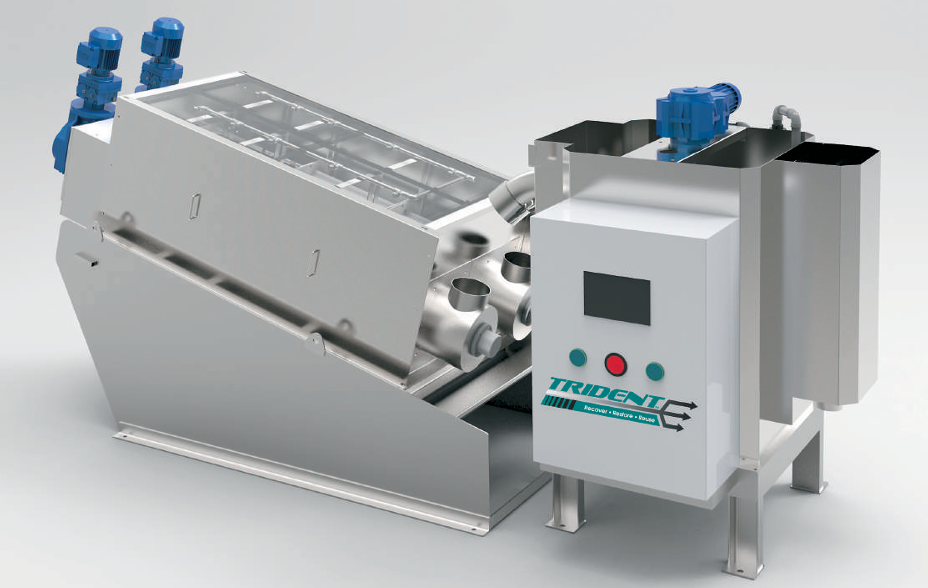

When is a waste a waste, and when is it a resource? Trident are leading the way in turning high solids waste streams into a valuable resource, creating an additional value stream for their municipal, food, brewing and agricultural clients.

Trident is a World leader in sludge thickening and nutrient recovery technologies. Their MD Press and Wave Separator are exceptional products designed to work in the harshest conditions. Both design with durable materials, these robust machines will work tirelessly, creating a high-solids cake, with minimal solids loss.

Ideally suited for dealing with the wide range of municipal solids seen at most treatment plants. Scalable to any size, with low operations and maintenance requirements.

Reduce volume and increase solids concentration, reducing disposal costs significantly.

With a high tolerance for fragile sludge, the Wave Separator in particular is perfectly suited to deal with fragile DAF sludge.

Recover the spent grain with high solids, reducing odour impacts and providing the user with a high-solids waste product.

With the moving discs, these units will not block with fish scales like a normal screen filter. The constant movement means there is little chance for blockage.

Turning a waste product into a valuable resource, many clients are making the most of livestock manure, turning this Nitrogen and Phosphorus rich waste into a pelletised fertilizer for land application.

With the ability to run multiple units from a single control panel, these systems allow for an unlimited throughput in volume and solids load.

Continuous self-cleaning process ensures consistent throughput of material.

Systems are designed to be self-cleaning, minimising costly shutdowns and time offline.

Small footprint = less civil construction, less CO2 emissions, and importantly, low overall capex.

All units run on variable speed drives, allowing for control of power usage throughout the desludging process. By controlling motor speed, these units will cut the energy required for processing significantly.

Made from all stainless steel, these units are built to last, and will survive in even the harshest of conditions.

Trident Wave Separator and MD Press work in a range of complex applications, but their operation is simple, intuitive and easy to lear, reducing training time on start-up.

Simple drive with minimal parts, located internally, away from the material being processed, these units have a quiet operation and are vibration free, minimising maintenance required.

Fully designed and fabricated in Western Australia, this groundbreaking AquaVoda Silicon Carbide Membrane Skid has

AquaVoda and Cembrane are thrilled to announce an exclusive partnership, giving AquaVoda full responsibility for

AquaVoda and Amiad are partnering with major iron ore companies to tackle environmental challenges head-on

Let's work together

If you have a technology that can meet these selection criteria and are looking

for representation in Australia, New Zealand and/or the South Pacific Islands,

please get in

touch!

Contact details

Copyright 2025 AquaVoda Pty Ltd | ABN 62 101 084 771